Ceramic Anilox Engravers manufactures a wide range of anilox solutions designed for ultimate success in flexographic printing and converting operations. View more CAE solutions, here.

Corrugated Adhesive Glue Sets

Advanced Ceramic Corrugated Adhesive Glue Sets

CAE produces high quality ceramic glue sets that deliver accurate and controlled starch/glue applications, job after job, time after time. Due to their advanced precisionin ceramic technology, in combination with advanced high definition laser engraving, CAE can produce tighter tolerances than that of conventional glue sets. This helps you to improve corrugated board quality while reducing your starch and glue consumption.

The difference between a production run that produced warped or “washboarded” corrugated boards or one that delivers straight, smooth corrugated boards can be as simple as controlling a few thousandths of an inch gap between the glue applicator and the doctoring rollers!

CAE’s Advanced Ceramic Glue Sets help you control the gap without the fear of insufficient gluing or crashing. How?

By using cutting edge coating and laser engraving technologies our customers are seeing the difference these technological advances deliver over the copper chrome glue sets predominantly in service.

Click "Make An Enquiry" on the right hand side to request a quote

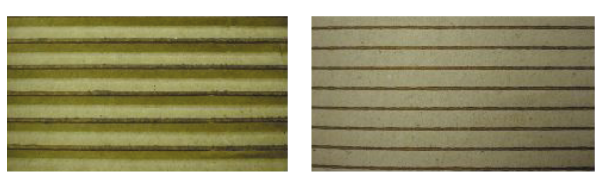

CAE Corrugated Adhesive Glue Sets

The images below show the uniform deposit of glue using CAE advanced ceramic glue sets.

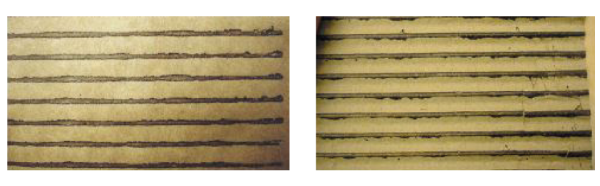

Conventional Corrugated Glue Sets

The images below show the glue application using a conventional line pattern glue set

CAE Corrugated Glue Sets Features & Benefits

- Resistance to corrosion and chrome flaking due to advanced coating properties

- Ceramic metallurgy offers improved lifespan over that of conventional copper and chrome compositions

- Tighter geometric (TIR/OD) tolerances ensure the closest consistent gap across the web when compared to conventional glue sets

- Advanced superhard doctoring rolls offer a mirror finish with advanced Ra

- Reduced warp, curl and washboarding due to tighter tolerances

- Lower starch glue consumptions due to advanced cell geometries

- Advanced applicator cell configuration ranges offer improved uniform transfer across the web

- Faster speeds with easy job repeatability and consistency

- Faster, easier clean ups reducing downtime and waste