Wash Up & Inking Systems

Ink Wash Ups at the Press of a Button

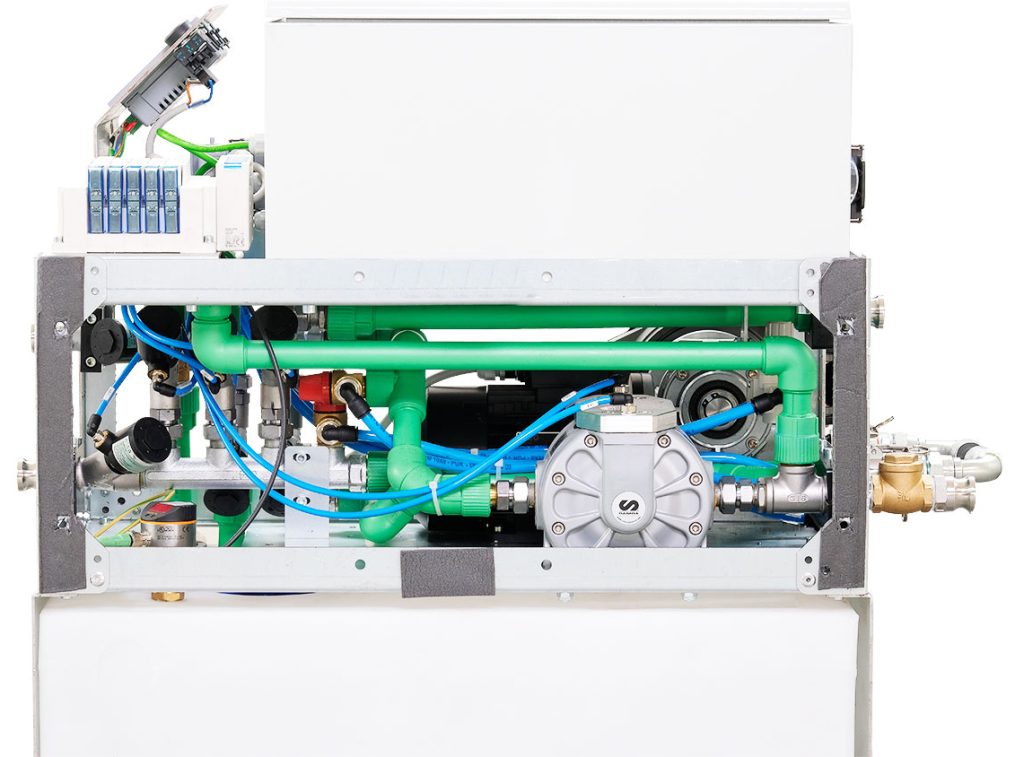

Say goodbye to the prolonged downtime and staff attention needed for your current inking and wash up processes, and say hello to the new BFT Flexo automated system. From start to finish, you can standardise your wash up process at the press of the button and save your settings for quick job setups and wash ups, every time.

The BFT system features optional extras of automatic viscosity, pH and temperature monitoring and control – taking the guess work out of inks and freeing up operator time.

The BFT Flexo system offers a reverse delivery pump capable of complete ink recovery of the feed lines, minimising ink wastage and providing a sharp ROI.

BFT Flexo Inking & Wash Up Systems

Features & Benefits

- Inking Control to Metering System

- Fast Wash Cycles

- Saved Settings & Recipe Recall

- Simplified Controls

- Fully Automatic

- Process Standardization

- Minimum Water Consumption

- Ink Recovery Capabilities

- Self-Diagnostic System

- Reduced Downtime & Waste

Integrate with Your BFT Carbon Fibre Chamber

UMS Australasia and BFT Group can integrate your BFT carbon fibre doctor blade chamber with your BFT Flexo ink wash up system, seamlessly.

Streamline your ink metering and wash up process for top print quality with minimal downtime.

Ask us how!

Manufactured by BFT Carbon

A complete inking system (inking and washing system + doctor blade unit) is also required by the OEMs. BFT Carbon is born to always have innovation among its products, it is a cutting-edge product made of carbon fibre with inside sensors able to communicate with the BFT Flexo system to optimise the process. View more BFT Group solutions available through UMS, here.