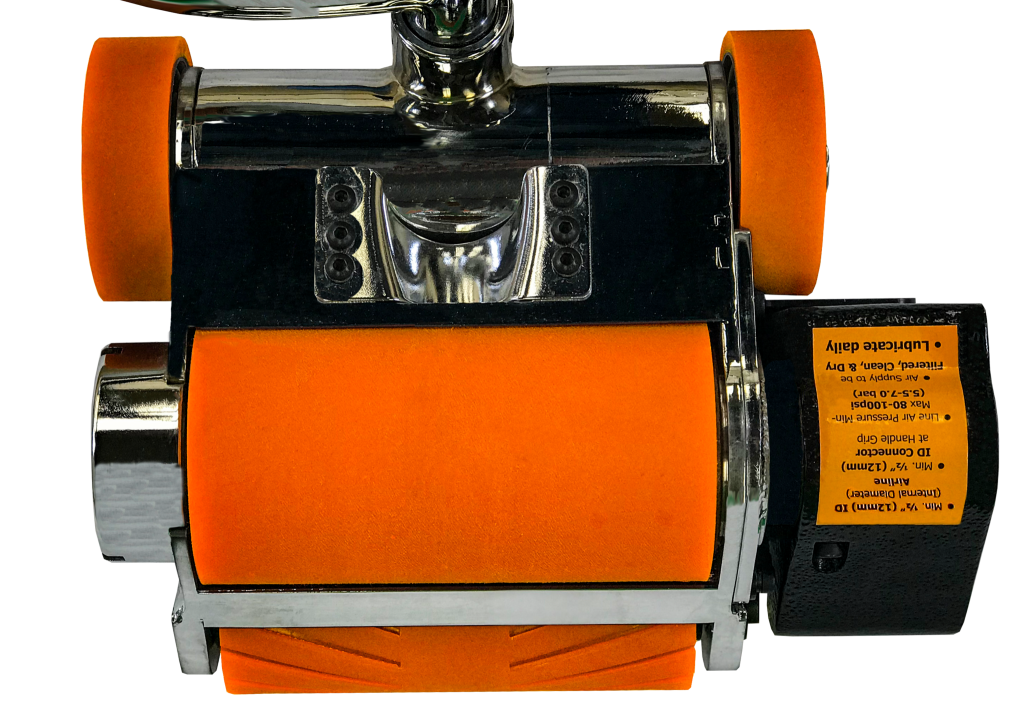

This pneumatic PowerRoll A-Series Roll Pusher is a range of compact, yet incredibly powerful devices that allow a single operator to safely, quickly, and easily move loads weighing up to 30,000kgs without a battery.

The premium, heavy-duty A-series features two of PowerHandling’s unique, worldwide Patented features:

- Direct Drive: for a zero-maintenance drive system

- Pivoting Rear Axle: Providing the unique ability to roll loads both forward (away from operator) & backwards (towards the operator)

All assembled into an even more compact and fully-enclosed frame.